Projects

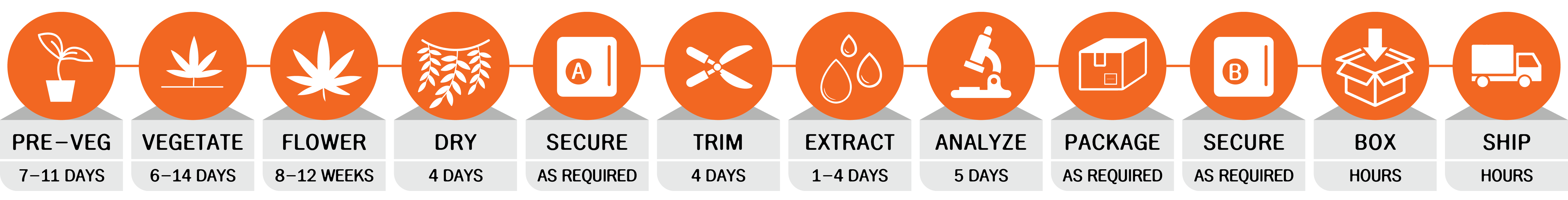

Production Process – ISO Certified

Highly automated from plant growing to processing, trimming, dehumidifying, oil extraction and finally medical products.

Cannabis strains are either pure or hybrid varieties of the genus Cannabis. Varieties are developed to intensify specific characteristics of the plant. Their names are typically chosen by their growers and often reflect characteristics of the plant such as taste, color, smell, or the origin of the varieties. Our goal is to cultivate varieties with a high percentage of Phyto cannabinoids. Phyto cannabinoids are cannabinoids that occur naturally in the cannabis plant. They are abundant in the viscous resin produced by the glandular structures of the cannabis plant called trichomes. Cannabinoids are defined as the terpenophenolic constituents of Cannabis sativa L. that interact with cannabinoid receptors in the human body, causing pharmacological effects. Phyto cannabinoids that are plentiful in the plant and the most pharmaceutically interesting are tetrahydrocannabinol (THC), cannabidiol (CBD), cannabigerol (CBG), cannabichromene (CBC) and cannabinol (CBN).

Seeds – Mother Plants

First, it should be noted that out of 100% of the seeds, 90% are selected for sowing and 10% are kept for mother plants. More specifically, the procedure is that the seeds will first be sown in trays of one centimeter depth and organic matter is added at a depth (> 3 cm) to allow the natural growth of the lower root portion before replanting. The substrate will have the ideal moisture content. The temperature is maintained at 20-25 ° C and the illumination level is adjusted to maintain for 16-18 hours daily. Ideally, the seedlings are ready for transplanting into individual pots. The cultivation will be done by hand and the growing medium is sufficiently watered to maintain moisture around the seedling.

Cultivation

Propagation is done by selected mother plants to ensure the highest harvest with a high drug concentration. High cannabidiol (CBD) plants are planted in a separate area in numbered rows and within five weeks their flowering stage is reached.

In the first three weeks, vegetative growth occurs with at least 16 hours of natural light. This results in a maximum growth rate allowing continuous photosynthesis. Since these are “small day plants”, flowering is naturally prevented by this method. The stage at which plants move from cultivation with relatively low light to high moisture levels and from propagation to high growth is carefully observed. The reason why it requires careful handling is to avoid ‘stressing’ the young plants, causing them to collapse.

Greenhouse control systems are developed to control the size and shape of the plants accordingly. During the growing season, plants are cut and shaped to achieve the best quality flower production. It is necessary to remove the lower leaved to allow air to flow, which also reduces the risk of disease. The “emptying” of the lower stem also contributes to the further development of the plant in height.

Plants with high THC content are placed in special containers in a standard growing medium (Grodan) and then placed in growing rows at a density of sixteen to eighteen plants per square meter five weeks before flowering. Part of the plant material is maintained in conditions that extend the length of the day to produce plant material.

Growing - Flowering

The plants are relocated to another area of the greenhouse or the lighting management will be adjusted accordingly to provide permanent lighting for the plants. This numerical process is interpreted as twelve (12) hours daily and twelve (12) hours a night. The change to a short day activates the plants and the flowering period is from seven (7) to fourteen (14) days. The short day length is maintained for the entire flowering period, which usually lasts eight (8) weeks.

During this period, the automatic system changes the lighting spectrum (LED) from the vegetative phase to the flowering phase. Throughout the harvest and flowering period, the plant’s automatic control system precisely maintains the ideal conditions in each area in terms of lighting requirements, spectrum, shading, temperature, humidity levels, CO2, as well as the required quantities of irrigation.

Biological Pest Control

Treatment of pests is achieved by using their natural enemies, i.e parasitic, predatory and pathogenic microorganisms. The properties of ideal natural enemies for their greater effectiveness in biological control are the pest specificity, synchronization of their biological cycle with that of the pest, their high reproductive capacity, high findability and ability to search and move. Beneficial organisms are therefore used to “feed” harmful herbivores and mites with the ultimate goal of producing quality products with zero chemical residues.

The main enemies of the crop are red spider mites (Tetrany chusurticae), thripstabaci, white fly (Trialeurodesvaporariorum) and aphid (Aphis gossypii). By introducing best practices for their management, pests will be controlled:

- with the regular introduction of Phytoseilius persimilis (predatory mite) to treat the double-headed chickpea.

- the regular introduction of Amblyseius cucumeris (predator mite) to treat thrips.

- with the regular introduction of Encarsia formosa (parasite) for the treatment of greenhouse mites.

- the regular introduction of Aphidius colemani (parasite) against aphids

Harvesting

Harvesting cannabis flowers at exactly the right time is crucial for optimizing the active ingredient content of the flower.

The right time to harvest depends on the cultivation of the cannabis strain and the active ingredient. Timing can vary from a few days to a few weeks between different cannabis varieties. For most strains, the window for optimal harvest is narrow – a few days at best.

During harvest, plants are cut and the lower part of the plant is removed using Mother Bucker machines that separate the stem from the rest of the plant.

The upper part of the plant, which contains the flower after separation, is processed in Twister machines where the flower is clearly separated from the stem, leaves etc.

A further hand trimming process provides the final fresh flower, which can bes used in the next stages of production.

Crop Treatment

Freshly separated pure flowers are transferred to the drying and storage phase prior to extraction. During this process, the flowers are placed in an industrial desiccator/dryer or drying chamber to reduce their moisture and to dry them. Fresh flowers has a water content of about 80% and are considered dry enough for storage or treatment when the water content is below 15%.

Garbling

This process is the final step in the production of a raw drug and involves the removal of foreign matter such as other parts of the plant, dirt, and added adulterants.

When grown in the glasshouse, minimal adulterants or contamination with dirt occurs. The presence of low-potency stem material is undesirable, and all material that has a diameter greater than 2 mm is automatically removed using a special bud sorting machine.

Storage Of Dried Flowers

As with other dried herbs, the water content of stored dried herbs is greatly affected by the surrounding humidity. To minimize the possible effects of varying moisture levels on microflora activity, secondary metabolite volatilization and catabolism, the herbal material is stored in a controlled environment at 35 ± 5 % RH. Low humidity is achieved by using industrial dehumidifiers. THC degrades more rapidly in the presence of light (Fairbairn 1976). To prevent this, the material is stored in the dark prior to analysis or use. After the material is dry enough for processing, it is placed in sealed bags with moisture control packaging and then placed in larger sealed boxes for storage.

Preparation for Oil Extraction

Dried flowers (bud) are taken from the sealed bags for further processing and oil extraction. A shredder and a milling machine are used to grind the buds into the thinnest possible powder for use in the oil extraction process.

Supercritical Co2 Cannabis Oil Extraction

Supercritical fluid extraction (SFE) is the process of separating components from each other by using a specific type of solvent. Such solvents are referred to as “supercritical” because when exposed to extreme temperatures and pressures they display structures that fluctuate between intermediate states of solid, liquid, and gas.

In this state, supercritical fluids are capable of breaking up structures where they can then be separated or fractioned. Among the variety of supercritical solvents used for this process, the most common by far is CO2.

Oil Refinement & Decarboxylation

Cannabis contains over 100 active compounds known as cannabinoids, that exist in the trichomes of raw cannabis flowers. THC and CBD are the two best-known, but there are so many others. For example, there is a lot more tetrahydrocannabinolic acid (THCA) found in raw cannabis than THC. THCA and cannabidiolic acid (CBDA) are precursor compounds to THC and CBD of their non-acidic counterpart.

THCA and CBDA are almost exactly the same as THC and CBD, but with an additional carboxyl group (some extra atoms). When the THCA is heated (by vaporization for example), this carboxyl group is lost and it becomes THC. The same goes for CBDA transforming into CBD. This chemical process is known as decarboxylation.

THCA doesn’t offer the same effects that THC does, including THC’s psychoactive properties. After heating and decarboxylation, THCA is converted into THC. CBDA creates its own effects within the body, however CBD is more bioavailable. Bioavailability is the degree and rate at which a substance or drug is absorbed into the body’s system. When a drug is administered intravenously, its bioavailability is 100%. However, this number decreases with other consumption methods such as oral or inhalation.

The distillation method occurs through a process called “short path distillation” which separates and refines valuable molecules as well as contaminants, resulting in a clean and practically transparent concentrate. In comparison to other refining methods, the distillate is at a higher level because it obtains a pure oil of very high potency. This method delivers ultra-premium THC distillate oils that can reach up to 90% potency.

Production of Finished Products

Oil

The pure and transparent high purity oil as a final product is packed in 250 ml, 500 ml and 1000 ml dark glass bottles and stored in a secure place with controlled access. This oil is intended for direct delivery to the pharmaceutical industry for the production of drugs and derivatives or for the manufacturing of capsule or oil packs in small dropper bottles.

Oil for oral intake with a dropper

The clear and transparent high-purity oil as a final product is packaged in 5 ml, 10 ml, 30 ml and 50 ml glass bottles and stored in a secure place with controlled access. This oil is intended for direct disposal as a final packaged product.

Capsule production

The capsule is produced by a special machine where the high-purity oil is encapsulated with other ingredients based on a medical formula or on its own. The produced capsules are packed in blister packs and cartons with instruction leaflet and are available as a finished packaged product.

Production ofTea Packaging

Part of the dried flowers, stored in special airtight packages after being cut into small pieces, are packed into tea bags using a special weighing / grinding packaging machine. The produced tea bags are packed in a package with an instruction leaflet and are available as a finished packed product.

Water Supply and Management

Growing is based on hydroponics with increased water demand coming from the drilling source. The water is treated by osmosis and infrared screening, and the water from the hydroponic culture drainage is collected in tanks, filtered and reused.

SGR-Kargos One AE

Status:

- land acquired

- governmental license issued

- architectural drawings completed

Total area: 51’158 m²

Production Capacity: 7’128 kg Oil / year

Timeline:

- Building permit by Q4, 2021

- Build greenhouse and main building by Q2, 2022

- Fully operational by Q2, 2022

Location: 78km north of Athens

Project Orestiada

Status:

- land contracts

- governmental license request to be started

- further land plots in discussion

Total area: 672’000m²

Production Capacity: estimated 94’000 kg Oil / year

Timeline:

- Governmental license by Q4, 2021

- Fully operational by Q4, 2022

Location: Orestiada

…to be continued…